Thermal Mass Flow Meters and Controllers

With decades of expertise in flow measurement, iCenta Controls supplies reliable thermal mass flow meters for accurate monitoring of gas flow. Using heat transfer principles to determine flow velocity, they deliver repeatable data without the need for moving parts. Ideal for applications such as compressed air, natural gas, and process gases, our thermal mass flow measurement offers dependable performance and easy installation.

Need help choosing the right meter? See our Thermal Mass Flow Meter Selection Guide.

What is a Thermal Mass Flow Meter?

A thermal mass flow meter measures the flow of gases using heat transfer, with no moving parts for high reliability. These meters provide accurate mass flow measurement for clean, dry gases such as compressed air, Nitrogen natural gas, nitrogen, hydrogen, oxygen, Co2, biogas and many other gases. They are ideal for applications where precision and efficiency are essential, including process control, HVAC, and environmental monitoring.

How Do Thermal Mass Flow Meters Work?

Mass flow meters introduce heat into the gas stream and measure how quickly it is carried away by the flowing gas. The rate of heat dissipation is proportional to the mass flow, and sensors convert this into an electrical signal representing flow rate. This method allows accurate, low-maintenance measurement without needing pressure or temperature compensation.

If you need further help, please visit our guides section below or contact our expert team for tailored advice.

Thermal Mass Instruments from iCenta Controls

Thermal mass flow meters provide a precise, reliable solution for measuring the mass flow of gases across a wide range of industrial and commercial applications. At iCenta Controls, we supply high-quality thermal flow sensors ideal for a wide range of gas monitoring, where accuracy and efficiency are critical. Gases are detailed below:

Nitrogen – N₂, Oxygen – O₂, Hydrogen – H₂, Carbon dioxide – CO₂, Carbon monoxide – CO, Methane – CH₄, Ethane – C₂H₆, Propane – C₃H₈, Butane – C₄H₁₀, Ammonia – NH₃, Ozone – O₃, Sulfur dioxide – SO₂, Sulfur trioxide – SO₃, Nitrous oxide – N₂O, Nitric oxide, NO, Nitrogen dioxide ,NO₂, Chlorine, Cl₂, Fluorine, F₂, Helium He, Neon – Ne, Argon – Ar, Krypton – Kr, Xenon – Xe

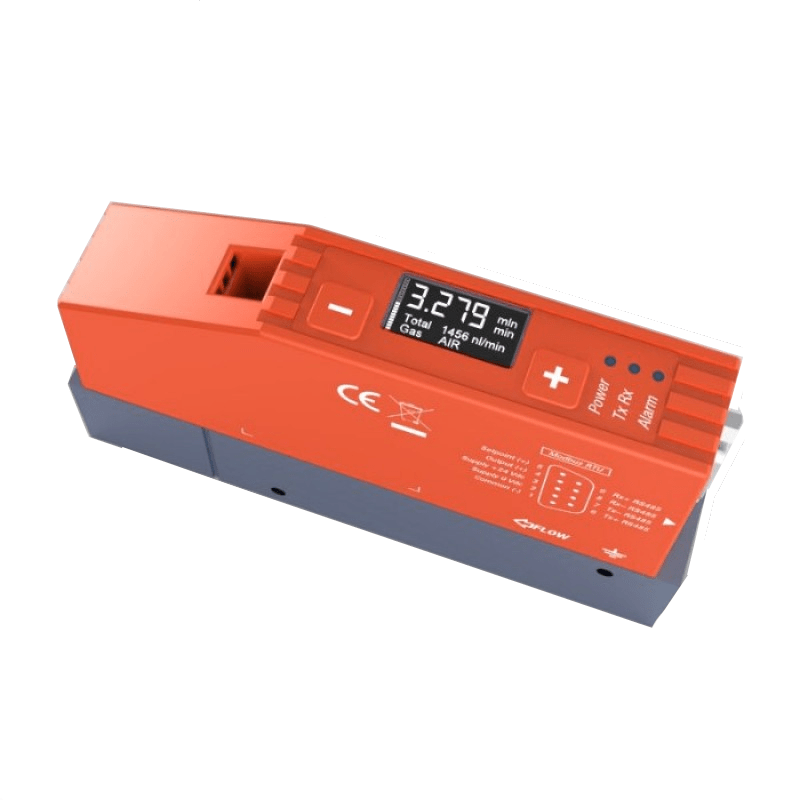

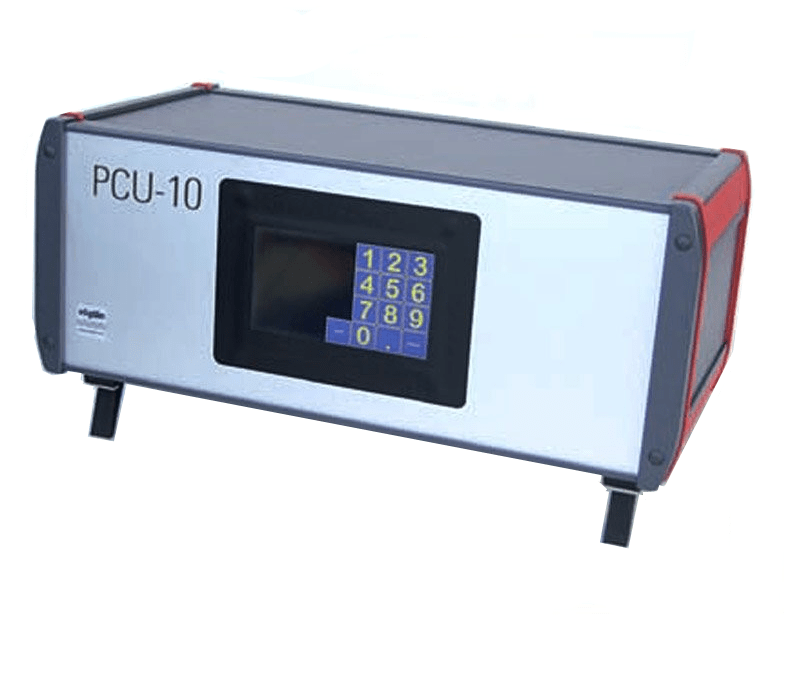

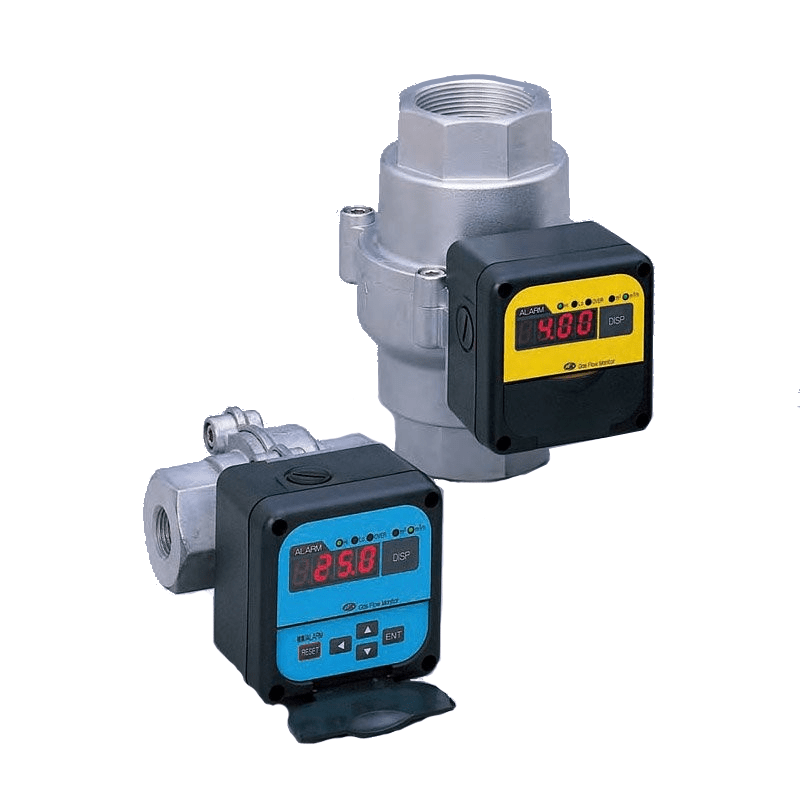

Our portfolio includes trusted global brands such as Vögtlin, Oval and CS instruments. These meters deliver dependable performance with easy installation, minimal maintenance, and seamless integration into control systems. Whether you need monitoring, mixing, process optimisation, or energy management, iCenta offers thermal flow measurement solutions backed by expert technical support.

Why Are Thermal Mass Meters Important?

Thermal mass flow meters provide an accurate way to measure the mass flow of gases across a variety of industrial and commercial applications. They help to:

- Deliver precise, repeatable gas flow data – ideal for compressed air, natural gas, nitrogen, and biogas monitoring.

- Offer straightforward installation and minimal maintenance, with inline and insertion models suited to different pipe systems.

- Handle a wide range of flow rates and pipe sizes, providing flexibility for diverse industrial processes.

- Reduce operating costs with durable designs and long-lasting components.

- Integrate easily with monitoring and control systems via electronic or digital outputs.

Our thermal mass flow meters provide dependable gas flow measurement for energy management, process control, and industrial applications.

What Are the Different Types of Thermal Mass Flow Meters and Controllers?

At iCenta Controls, we offer a versatile range of thermal mass flow meters designed to meet diverse gas flow measurement needs. The most common types include:

- Inline Thermal Mass Flow Meters: Installed directly in the pipeline, these provide accurate, repeatable measurement for compressed air, natural gas, and other process gases.

- Insertion Thermal Mass Flow Meters: Fitted into existing pipework without disrupting flow, ideal for large ducts, retrofits, or industrial installations.

- Low-Flow Thermal Mass Flow Meters: Optimised for precise measurement of small gas volumes, perfect for chemical dosing, laboratory processes, or calibration applications.

- High-Temperature or High-Pressure Thermal Meters: Engineered for demanding environments, delivering reliable performance under elevated temperatures or pressures.

In What Industries Are Mass Flow Meters Used?

Mass flow meters and mass flow controllers are used across many industries, especially where precise gas or liquid flow control is critical. The major sectors include:

1. Semiconductor & Electronics Manufacturing

- Process gas delivery (etching, deposition, doping)

- Ultra-high precision requirements

This is one of the largest users of mass flow controllers (MFCs).

2. Chemical & Petrochemical

- Reaction control

- Gas blending

- Catalyst research

- Pilot plants and process scale-up

3. Pharmaceutical & Biotechnology

- Fermentation gas control (O₂, N₂, CO₂)

- Bioreactors

- Precise dosing of solvents and gases

4. Food & Beverage

- Modified atmosphere packaging (MAP)

- Carbonation systems

- Controlled gas dosing (CO₂, N₂)

5. Environmental & Energy

- Emissions monitoring

- Fuel cell development

- Combustion research

- Biogas measurement

6. Medical & Healthcare

- Respiratory equipment

- Anesthesia gas mixing

- Laboratory instruments

7. Automotive & Aerospace

- Engine testing

- Exhaust analysis

- Fuel system calibration

- Spacecraft environmental control systems

8. Research & Laboratory Applications

- Gas mixing trains

- Flow experiments

- Analytical instruments (GC, MS, FTIR)

9. Industrial Manufacturing

- Welding and cutting gas control

- Furnace atmosphere regulation

- Leak testing

- Coating systems

How Can Thermal Mass Flow Meters Positively Impact Your Business?

Thermal mass flow meters provide precise, real-time measurement of gas flow, helping optimise process control, energy management, and operational efficiency. They are especially useful for monitoring, blending (mixing), and dosing applications where accurate mass flow data is critical and the cost of bespoke purchased gas mixtures can be avoided.

They also support improved process stability by offering consistent, drift-free measurements even when temperature or pressure conditions fluctuate. This reliability makes them a valuable tool for industries aiming to reduce waste, enhance safety, and maintain tighter control over gas consumption.

With no moving parts, minimal maintenance, and fast response times, thermal mass flow sensors deliver reliable long-term performance and lower lifecycle costs. Our range ensures accurate, dependable gas flow measurement tailored to your specific business and process needs.

In addition, their robust construction and flexible installation options make them suitable for both new systems and retrofit projects, allowing businesses to upgrade measurement capability without major disruption.

Please visit our case studies below for real-life mass flow applications or speak to our team of experts.